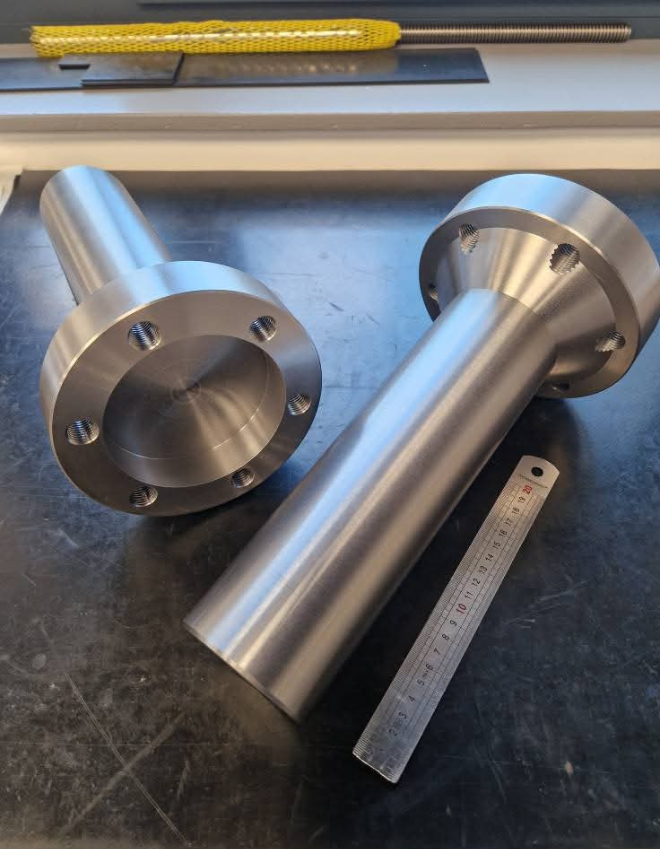

Conventional milling: reliable solution for your custom parts

Conventional milling is an ideal mechanical process for simple or one-off machined parts, especially for modifications, repairs or manual adjustments. This traditional machining technique remains widely used for its flexibility, responsiveness and precision, particularly when no digital file is available. Our workshop produces your custom parts in small batches or single units, in various materials: steels, aluminium, plastics, etc.

Why choose conventional milling?

Manual milling remains a reliable and flexible process for quickly machining simple, one-off or modified parts. It allows precise adjustments and direct intervention, ideal for repair, rework or prototyping.

Fast and flexible

Perfect for small batches, touch-ups or urgent needs, without complex programming.

Suited to simple parts

Ideal for machining flats, holes, grooves or mechanical adjustments by hand.

Full manual control

Manual milling allows real-time adjustments, useful for maintenance or part modification.

Materials suited to conventional milling

Conventional milling remains a reliable solution for machining many materials. It is ideal for rework, single-part manufacture or custom parts, with excellent manual control and great flexibility.

Where are manually milled parts used?

Conventional milling remains a reliable solution for quickly machining simple or one-off parts. Here are some typical application areas.

Mechanical industry

Flats, holes, grooves

Aerospace

Single parts, touch-ups

Automotive

Shims, supports, adjustments

Rapid prototyping

Simple parts, trials

Industrial equipment

Flanges, bases, fixed elements

R&D and laboratories

Small batches, fitting

Personal projects

One-off parts, restorations