CNC milling

Ideal for machining complex shapes, grooves, pockets or multiple drilling operations.

Conventional milling

Compatible with metals, alloys, plastics and engineering materials.

Why choose milling?

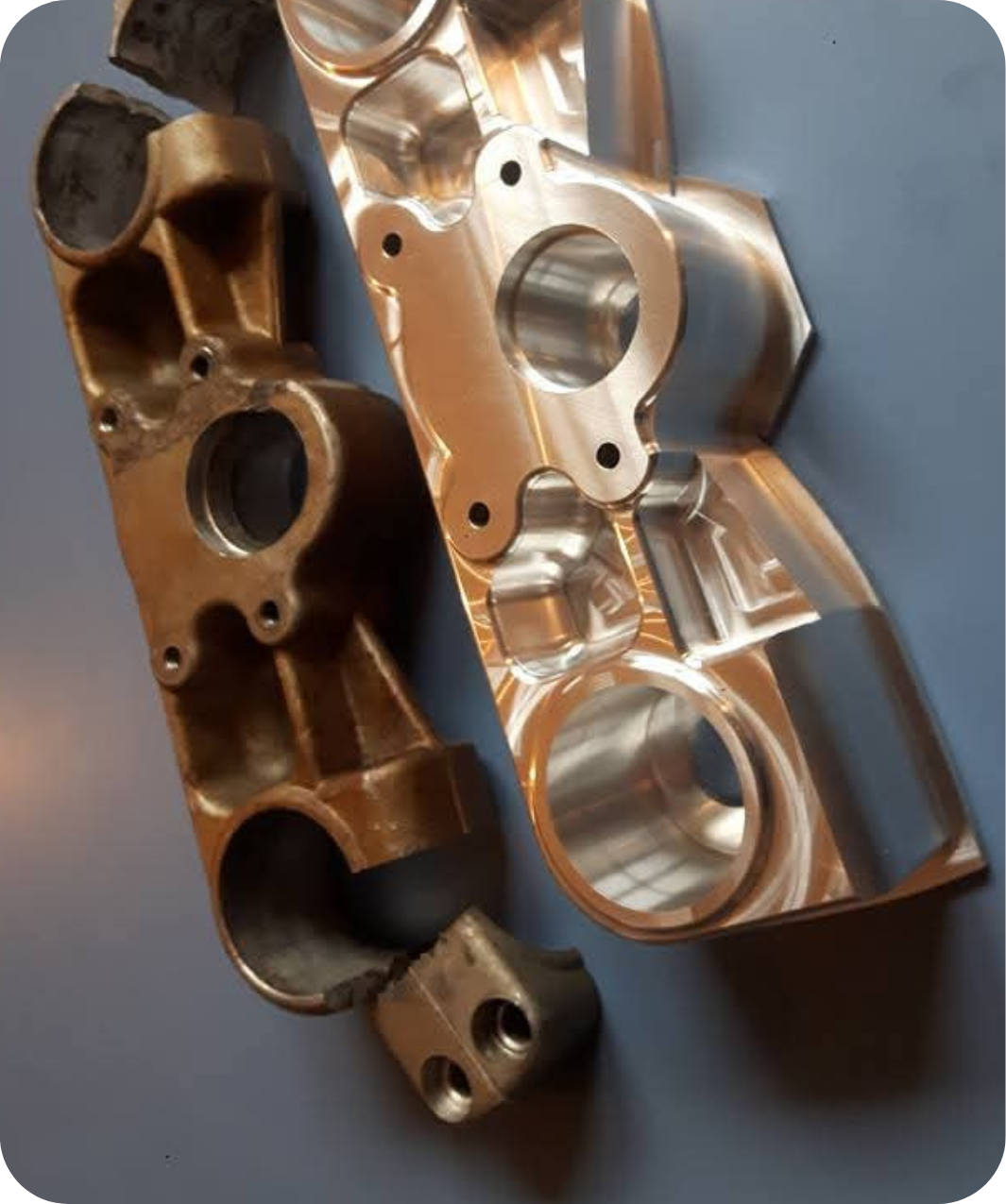

Milling creates complex parts with precise tolerances. This method is ideal for producing high-precision components in various materials, from plastic to metal alloys, ensuring exceptional quality at every step.

Precision and tight tolerances

Our milling machines offer tolerances down to ±0.01 mm, enabling complex parts with extreme precision. These tolerances are especially important for sectors requiring critical parts, such as aerospace and precision engineering.

Minimum and maximum machinable sizes

We can machine parts from a few millimetres up to maximum dimensions of 1000 mm x 600 mm x 500 mm. This size flexibility allows prototypes as well as production parts for various applications.

Complex threading and drilling

Milling enables complex threading and drilling with high-precision finishes. We offer internal and external threading options to suit your industrial needs, ensuring parts ready for assembly.

Materials compatible with milling

Milling can machine complex shapes across a wide range of materials. Discover the most used metals and plastics for robust, precise and functional milled parts.

Industries using milled parts

Milling enables the manufacture of complex parts in varied shapes. Many sectors use this technology for technical, precise and custom components.

Mechanical industry

Supports, flanges, housings and plates machined to order.

Aerospace

Structural components milled in aluminium or titanium.

Automotive

Housings, flanges, fasteners and engine parts machined with precision.

Rapid prototyping

Functional 3D parts for mechanical validation and assembly.

Special machinery

Machining of frames, bases, slides and technical fasteners.

R&D and laboratories

Parts machined to drawing for test devices or tooling.

Custom projects

One-off parts for architecture, art or mechanics.