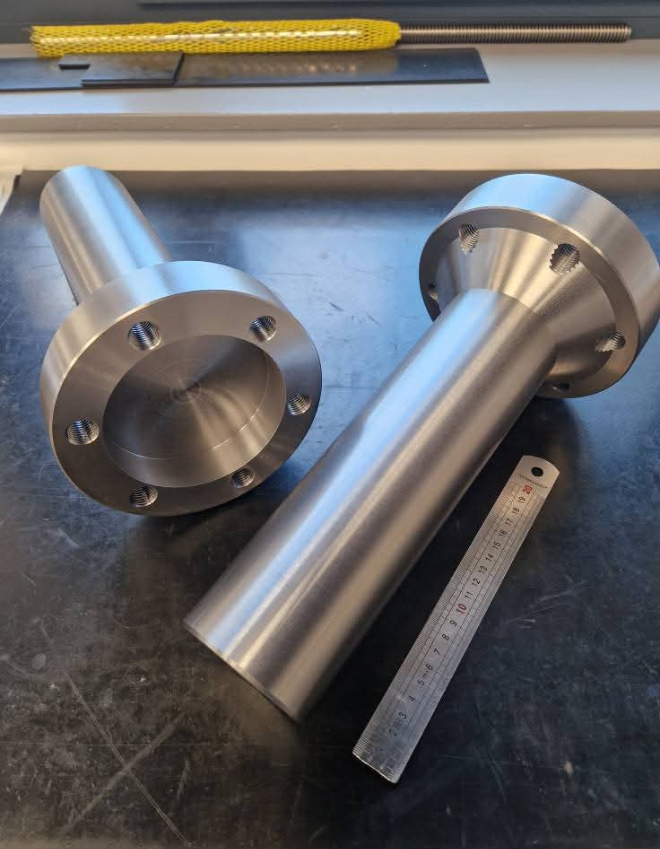

CNC turning

Ideal for machining complex cylindrical parts with micrometric precision. Perfect for repeatable series and technical geometries.

Conventional turning

Suited to small batches, repairs or manual adjustments. Offers flexibility, responsiveness and traditional know-how.

Why choose turning?

Turning is an extremely versatile manufacturing process. It offers tight tolerances, flexibility to work with various materials, and enables complex parts with an excellent quality-to-cost ratio. Discover the many benefits of this technology.

From single parts to large series

Whether you need a prototype, a replacement part or hundreds of units, you get the same level of precision and quality follow-up.

Machinable metals and plastics

Working with stainless steel, aluminium, brass or engineering plastics? We adapt our tools to your materials for optimal performance and finish.

CNC or conventional depending on your project

Benefit from CNC turning efficiency for complex parts and conventional turning flexibility for rework or economical small batches.

Fast, reliable lead times

Urgent need? Thanks to our agile organisation, your parts are produced in short lead times while meeting your technical requirements.

Technical support

Have an idea, sketch or incomplete drawing? We help you optimise your part for more reliable, faster and more economical machining.

Materials compatible with CNC turning

CNC turning is particularly suited to cylindrical or rotation-machinable materials. Here are the metals and plastics most commonly used for precise, strong and functional turned parts.

Industries requiring precision turned parts

CNC turning produces essential cylindrical parts in many industrial sectors. Discover the main fields where these components are indispensable.

Mechanical industry

Shafts, axles, bushings and spacers for industrial machinery.

Aerospace

Rotating components, sleeves and high-precision fasteners.

Automotive

Wheel axles, ball joints, pistons and machined engine parts.

Rapid prototyping

Cylindrical part testing before series production.

Industrial equipment

Custom wear or connecting turned parts.

R&D and laboratories

Parts to drawing for experimental devices.

Personal projects

Custom part manufacturing or mechanical restorations.