3D printing at Lusinage

3D printing enables fast manufacture of custom parts, whether prototypes, visual models or technical parts. We use several technologies and materials to meet all your needs.

Why choose 3D printing?

3D printing is an economical and fast way to produce functional parts or prototypes. It enables complex shapes without specific tooling, with a wide variety of engineering thermoplastics.

Free forms without constraints

FDM printing enables parts with complex internal geometries, hollow structures or nested assemblies without moulds.

Fast, economical production

With no tooling or machining required, FDM parts can be produced in hours at low cost, ideal for concept validation.

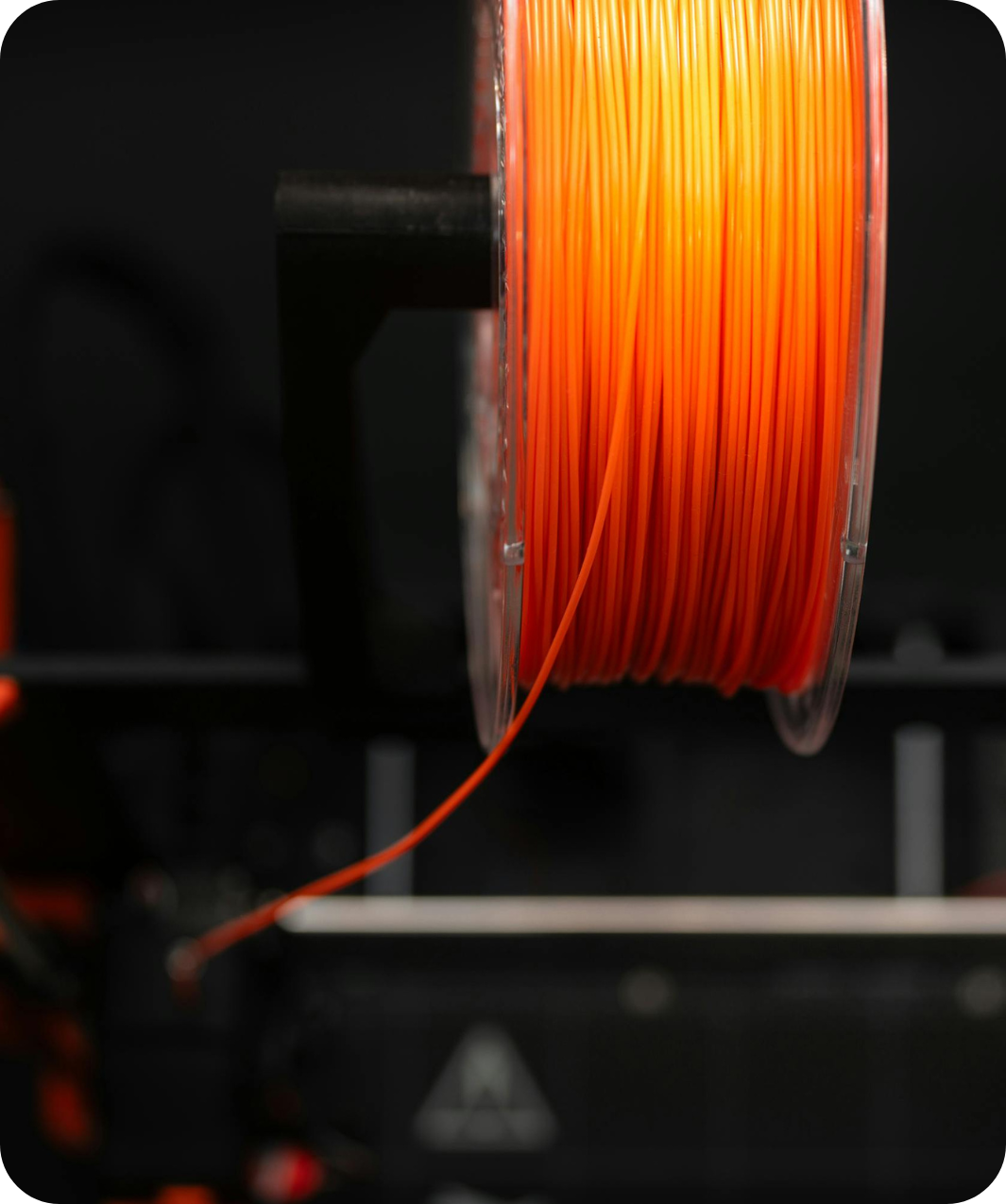

Wide choice of thermoplastics

PLA, PETG, ABS, ASA, TPU... each material has its properties: mechanical strength, flexibility, heat or UV resistance.

Materials compatible with 3D printing

3D printing works with a wide variety of engineering plastics. Each filament has specific properties to suit your mechanical, thermal or aesthetic constraints.

Industries using additive manufacturing

3D printing, whether filament (FDM), resin or selective sintering (SLS), has become a key technology for rapid prototyping, custom production or technical parts. It adapts to many sectors thanks to its flexibility, speed and low cost.

Mechanical industry

Supports, jigs, housings, custom tooling.

Rapid prototyping

Models, form trials or functional parts.

Design & architecture

Complex objects, models or decorative elements.

Education & training

Visual aids, technical models, demonstrators.

R&D & laboratories

Parts to drawing, tests, trial components.

Personal projects

Repairs, one-off objects, custom solutions.